Even though people increasingly recognise the plastic pollution threat, we have used more plastic since the covid-19 pandemic began. In the US, for example, demand for flexible plastic packaging grew by around 4-5% in 2020, according to consulting firm Wood Mackenzie. That painful paradox reflects plastic’s usefulness – but is also making some people want to avoid its disadvantages, including with the help of bio-based plastics.

Hasso von Pogrell, Managing Director of European Bioplastics

Hasso von Pogrell, Managing Director of European BioplasticsHasso von Pogrell, Managing Director of European Bioplastics in Berlin, Germany, which represents the continent’s bioplastics industry, explained why we are relying on plastics so much. “Covid-19 has once again emphasized the many advantages of plastic and its unmatched material properties when it comes to health protection and sanitary standards,” he commented. “However, at the same time, the pandemic further intensified the challenges related to plastic waste. Although they are not the sole silver bullet everyone is looking for, bio-based as well as compostable plastics can help to tackle these challenges.”

Normally, we make plastics from fossil-based chemicals that originate from plants that grew millions of years ago and have decayed to become oil or gas. These are widely used to generate energy, releasing the planet-warming greenhouse gas carbon dioxide, but some components are also useful for making plastic. Meanwhile the long-lasting strength that makes plastics useful can also be a disadvantage, as waste plastic products linger in and pollute our environment.

In bio-based plastics, we swap fossil-based chemicals for alternatives from recently grown plants, which have absorbed carbon dioxide, or waste. Another advantage is that countries that don’t have oil and gas resources can more easily access raw materials for bio-based plastics.

François de Bie, Senior Marketing and Supply Chain Director

François de Bie, Senior Marketing and Supply Chain Director

at leading bio-based polylactic acid (PLA) producer TotalEnergies Corbion - credits TotalEnergies CorbionCovid-19 has changed consumer and business plastic demand, explained François de Bie, Senior Marketing and Supply Chain Director at leading bio-based polylactic acid (PLA) plastic producer TotalEnergies Corbion in Gorinchem, The Netherlands. “In the initial phase we saw a reduction in demand for food service ware and food packaging in industries that were impacted by the lockdown,” he said. “In food packaging in supermarkets we saw a strong increase in demand, as people bought more from supermarkets and were more concerned that what they bought was safely packed and with a long shelf life.” Meanwhile the medical industry sometimes used bio-based PLA for 3D printed parts for respiratory devices and hygienic face masks.

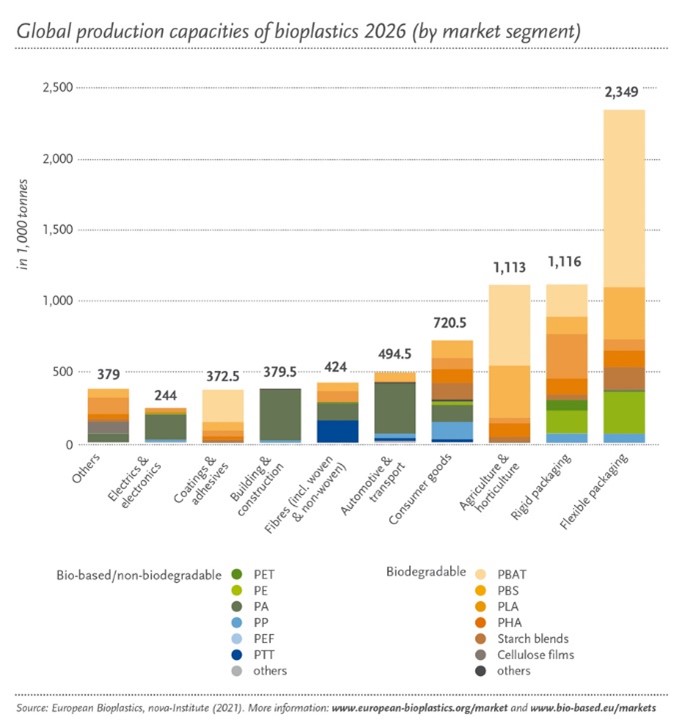

Von Pogrell explained that bio-based plastics usually have similar material properties to their conventional counterparts, and sometimes even better properties, such as additional recycling options. “Bio-based plastics have significant benefits over fossil-based plastics, especially when it comes to the reduction of carbon dioxide emissions and the desired independence from fossil resources,” he said. Product packaging uses nearly half of bio-based plastics, von Pogrell explained, their commonest use. “Unfortunately, still too often it’s the cheapest price that sells and this is usually the fossil-based plastic packaging.”

John Vos, Senior Consultant and Project Manager

John Vos, Senior Consultant and Project Manager

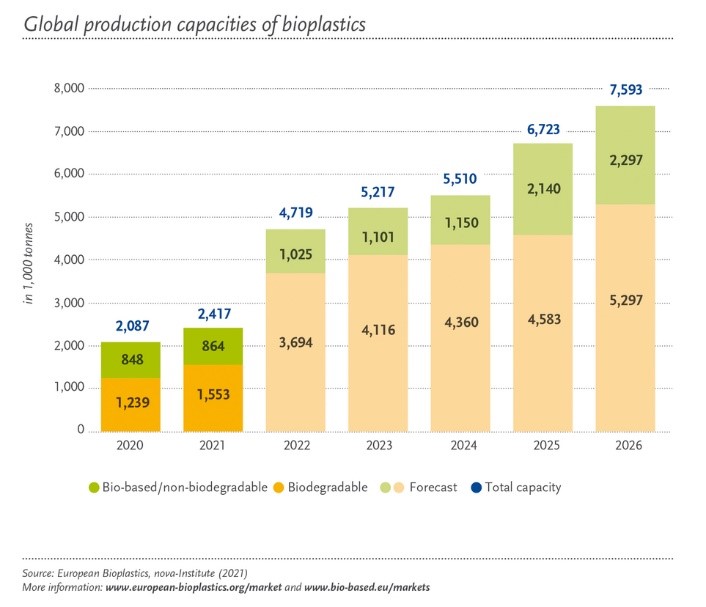

at Biomass Technology Group“Currently only 1% of plastics is bio-based,” added John Vos, Senior Consultant and Project Manager at Biomass Technology Group in Enschede, the Netherlands. “The rest is fossil-based.” Vos explained that demand for bio-based plastics has been growing faster than for fossil-based plastics since before the pandemic. A contributing factor may be the European Union (EU) plastic strategy specifying that by 2030 all plastic packaging entering the EU market must be either reusable or recyclable in a cost-effective manner.

Recent growth of some bio-based plastics could have been even stronger had there been enough production capacity available, Vos continued. Demand is strong, he explained. “The interest in the issue of sustainability has gained in importance, and this interest is growing more rapidly than before the pandemic,” he said. “Bio-based products can help deliver the sustainability demanded by consumers.” People are unlikely to ask for bio-based products, he noted, but their demand for sustainable products is an opportunity for this sector.

Vos works on various European projects exploring people’s relationships with bio-based products, including Allthings.bioPRO and BIOSWITCH. In BIOSWITCH, researchers from Finnish national research institute VTT asked focus groups of consumers about whether covid-19 had made them more cautious regarding bio-based product alternatives. Most participants responded that covid-19 had little or no effect on their consumption. Use of bio-based alternatives did increase, but not due to covid-19.

However, comments from a minority of participants suggested that the pandemic affected their consumption behaviour. “It has forced me to think about the overall situation of the planet, but not so much everyday consumption,” one said. “There is more time to pick berries” another commented, while another said they were now more likely to buy used clothes and toys. Another respondent said that covid-19 had caused less consumption since “because of the lack of eating out, culture, and entertainment”.

Meanwhile, like many industries, costs for bioplastics companies have increased significantly since the pandemic started, de Bie explained. That’s especially true for key raw materials, energy and transportation costs for finished products. TotalEnergies Corbion also had difficulties scheduling shipments, but that problem ended in early 2022.

Yet fossil-based plastics have also faced similar, and possibly even worse, issues. “The price difference between biobased and fossil solution has become a bit smaller recently,” de Bie said. “We see more consumers demanding more sustainable plastic solutions,” he added, noting that they are less concerned by a small price difference. “For all those early adopting consumers who, for example, drink organically grown tea or who eat bio-organic yoghurt the whole picture should fit,” de Bie explained. “The tea bag or plastic packaging should be biobased, compostable and with sound environmental credentials.”

And now, the conflict between Russia and Ukraine is intensifying problems. “Prices for all plastic materials as well as prices for industry goods in general have increased,” van Pogrell said. “Of crucial importance for the entire industry, conventional plastic as well as bioplastic, will be the increasing energy costs related to the production process. It is still too early to make sound statements about the effects of the current shortages in the supply of fossil resources. However, the current situation could have the potential to at least temporarily reduce the price difference between biobased and fossil-based plastics.”